In many industries, the Internet of things (IoT) is seen as the next key driver of business model innovation in the coming decades. The large analyst firms have tried to outdo each other with excited, multibillion-dollar predictions of revenue and GDP growth from the IoT. In fact, the transformational potential of the IoT is huge.

The basic assumption is that in the future, almost all products – consumer as well as industrial – will become more intelligent and leverage always-on connectivity to access value-adding services in the cloud or other back end.

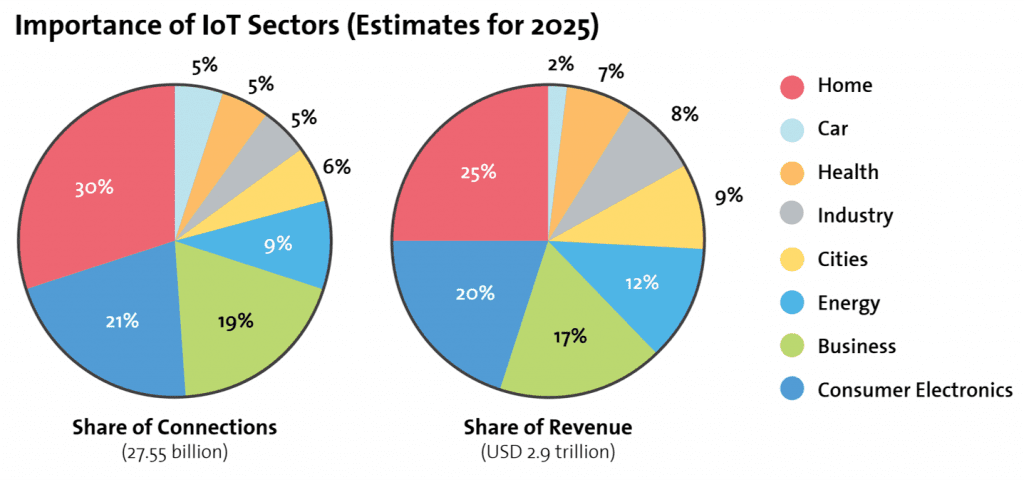

Industry analysts are still bullish on the growth potential of the IoT, as can be seen in the following figure.[1] While consumer devices, including homes and cars, have the greatest potential for growth on a per-connection basis, the industrial Internet of things (IIoT) is seen by many as the area with the largest revenue-per-asset growth potential, simply because industrial assets tend to be of higher value than consumer devices.

Applications and data will become increasingly distributed between the products and assets in the field on the one side, and the back-end services on the other. Being able to leverage data from multiple products in the field will enable IoT-style ‘wisdom of the crowd’-based applications.

A key pattern in the IoT is to distribute sensors in the field by attaching them to products and other assets, and to utilise the data gained from these sensors to create a digital image of the physical world.

This digital image can then be used for advanced analytics (e.g., to maximise in-store sales, better manage inventory, optimise the supply chain, improve hospital management and patient care, increase efficiency of energy management in buildings, or to implement advanced concepts such as predictive maintenance of home appliances and industrial machinery).

In the past decade, many IoT-based solutions have emerged that have a profound impact on our daily lives. Good examples are car-sharing services such as Drive Now or Car2Go; customers can use their mobile phones to locate the nearest available car. Once the customer has reached the car they want to use, they can use an RFID (radio-frequency identification) chip or their mobile phone to unlock the car. A telematics unit in the car unlocks the car, records actual usage and monitors events such as ‘low on fuel’. The combination of smartphones and IoT-based technologies is enabling these kinds of new, innovative services.

Some Internet companies are placing large bets on IoT-based business models. The multibillion-dollar acquisition of Nest by Google shows that companies like Google consider appliances such as thermostats and smoke detectors – and other physical products in the customer’s home – to be important interfaces with the consumer. It remains to be seen how successful Google and the likes will be in adapting their inherently data-based business models to the IoT.[2] The recent heated discussion about the decommissioning of back-end services by Nest – which effectively rendered the connected devices worthless – also shows the potential drawbacks of physical products that depend on cloud services.

However, despite the usual struggles of the early adopters and some legitimate security concerns associated with pervasive use of connected and communicating devices (at least per current state of the art), the industry remains bullish about the potential of the IoT for consumer products and the IoT for industrial applications.

This is not only because of the benefits for the end users, but also because many believe that the impact on manufacturers themselves will be equally strong. For manufacturers, the IoT has the potential to dramatically change their relationship with end customers. In the past, for most manufacturers the story ended once the product left the factory.

For example, once a car was sold, the manufacturer had no idea how the car was used, resold or repaired. Naturally, many car manufacturers try to establish a closer relationship with their customers (for example through service contracts). But still, the situation is difficult and many manufacturers remain unaware of how their products are used or how they perform in the field.

Naturally, the IoT promises to change all of this. During production, manufacturers can now take advantage of Industry 4.0 concepts (the manufacturing version of the IoT) to track parts as they move through the production process.

Once a connected product is sold, it gets even more interesting. Connected products usually require some form of activation or pairing the first time an end user begins to use them. This is a unique opportunity for manufacturers to create a digital connection with the end user (i.e., through the registration process).

If the user agrees, the manufacturer can then collect actual usage data from the product. Such data is invaluable. First of all, it provides real-world feedback to the product design team, who can use it to further optimise their products. Second, product usage data can be analysed and potentially used for up- and cross-selling purposes.

Many IoT products also allow the selling of additional digital services.

For example, a car manufacturer could offer to temporarily upgrade car performance remotely, for an additional fee. Maintenance and support processes for many products are also going to change because of the IoT.

Remote condition monitoring, preventive maintenance or even predictive maintenance (based on advanced analytics and machine learning) will increasingly become normal.

_____

[1] Buckland, E., Ranken, M., Arnott, M., Owen, P.: ‘IoT Global Forecast and Analysis 2015-2025’, Machina Research, 2016.

[2] Higginbotham, S.: ‘The Mess at Nest Echoes the Mess in the Smart Home’, Fortune, 2016.